On-Board Diagnostics

On-board diagnostics (OBD) is the continuous monitoring of all emission-relevant sensors and actuators of an engine system. The goal of this project is to develop and improve algorithms to accurately monitor the static and dynamic properties of these sensors and actuators over the whole lifetime.

Introduction

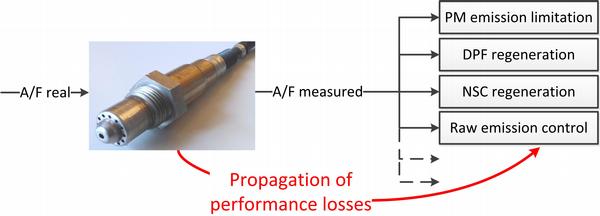

Increasingly stringent governmental regulations require engine systems to meet the emission legislation limits over their lifetime. To satisfy the regulations, several raw emission control systems and exhaust after-treatment systems are implemented, e.g. the transient full load soot limitation in Diesel engines using an exhaust oxygen sensor (see Figure 1). Fast and accurate sensors are a prerequisite for those control systems to work properly. However, especially the sensors in the exhaust path are exposed to a harsh environment, which can lead to sensor clogging. Particularly in Diesel engines the soot raw emissions can lead to clogging of the sensors placed in the exhaust pipe, e.g. the wide-range oxygen sensor (lambda sensor or air/fuel ratio sensor). Sensor clogging can lead to measurement errors such as offset and drift as well as slowed down sensor dynamics. Therefore, in compliance with the emission regulations, the static and dynamic properties of the sensors and actuators need to be monitored. Observed changes can be compensated using adaptive control techniques or might require the replacement of the defective sensor or actuator.

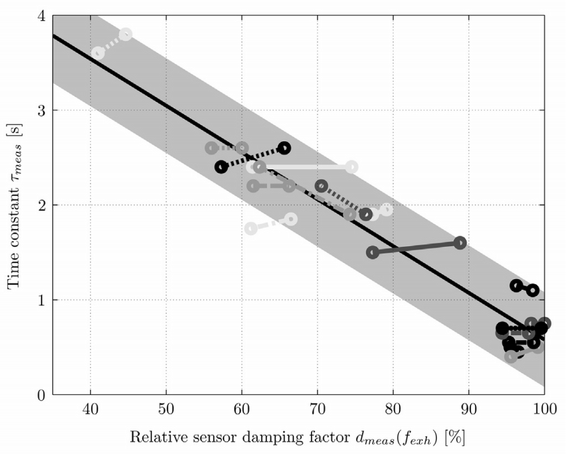

In the first part of the project, the research focused on the intrinsic properties of wide-range oxygen sensors. Based on these properties a new approach to diagnose the oxygen sensor dynamics was developed which exploits the fact that the wide-range oxygen sensor measures the oxygen partial pressure, which is proportional to the oxygen concentration as well as to the total pressure of the exhaust gas. Hence, the sensor input, which is the oxygen partial pressure, is excited either by a varying oxygen concentration or a varying total pressure of the exhaust gas. The proposed method to diagnose oxygen sensor dynamics makes use of the sensor excitation via the total pressure to be independent of the fuel injection excitation.

The method is based on the inherent reciprocating behavior of the engine, which causes pressure pulsations in the exhaust pipe. Due to the sensitivity of the oxygen sensor measurement on changes in the total pressure, these pulsations can be observed in the measurement signal and allow for an input/output analysis of the sensor dynamics (see Figure 2). This setup makes the approach passive and independent of the fuel excitation induced by the driver. For more details see [1].

Future research in this project focuses more generally on sensors for automotive applications of any type, such as NOx-sensors, temperature sensors or oxygen sensors. They have in common that their dynamic and static behavior usually depends on the operating point of the engine.

The goal is to develop algorithms that are able to monitor these sensor properties using the modeled sensor input signal and the measured output signal of the sensor. Major challenges are restricted computational and memory resources, high reliability irrespective of the excitation scenario induced by the driver and the dependency on the operating point.

10.2013: Auto&Technik

14.08.2013: Automobilrevue