Natural Gas Diesel Hybrid

The CO2 emissions in a vehicle are basically determined by the energy demands, the efficiencies related to the energy conversions and the mass specific CO2 emissions in the fuel.

Energy demands

The energy demand of a vehicle can be divided into two groups.

First the dissipative energies used to overcome aerodynamic friction, rolling friction and auxiliaries as for example light. These demands can be reduced by design features.

The second group of energies are of circulating nature, since they are converted energies and not directly lost. This group includes the kinetic energy based on the vehicle speed and the potential energy depending on the altitude profile. In the case of conventional vehicles, the energies will be lost in the brakes. In the case of hybrid electric vehicles, the energies can partially be recuperated.

Efficiencies

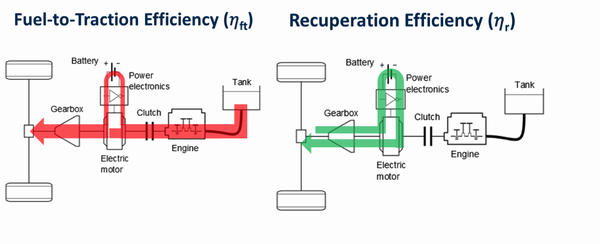

Many energy conversions occur in a vehicle. There are always losses if energy is converted from one type to another using a real process, which is often expressed as efficiencies. The efficiencies in a vehicle can be summarized by the Fuel-to-Traction- and the Recuperation efficiency.

The Fuel-to-Traction efficiency describes the losses that are originated from all transformation from the chemical energy in the fuel to the traction force at the wheel (see red path in Fig. 1).

The Recuperation efficiency describes all losses if kinetic or potential energy is saved in the battery during recuperation and again transformed into mechanical power at the wheel afterwards (see green path in Fig. 1).

Energy specific CO2 emissions

The CO2 of a fuel depend on ration between hydrogen and carbons. Natural gas has 25% less CO2 emissions bound at the same amount of energy in diesel or gasoline.

Motivation for a Natural Gas Diesel Hybrid

Among all possible natural gas engines, the dual-fuel natural gas-Diesel engine is one of the most promising engine types. It has the potential of achieving Diesel-like efficiencies without the need for a lean nitrogen oxide aftertreatment system. It also benefits from the lower CO2 emissions of natural gas compared to diesel or gasoline.

The natural gas diesel engine is optimally complemented by an electrical hybridization. This not only allows for recuperation of kinetic and potential energy, this also allows a reduction of part-load conditions and operating point shifting. This improves the the fuel-to-traction efficiency noticeably.

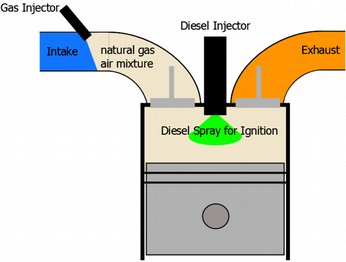

The dual-fuel natural gas-diesel combustion concept

In the dual-fuel engine, the natural gas is injected into the intake manifold. Instead of using a spark plug for ignition, the premixed air-gas mixture is ignited with a small amount of directly injected Diesel fuel.

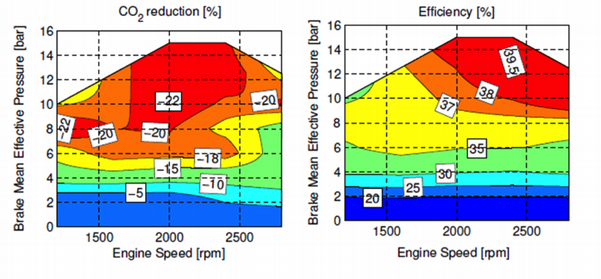

There are more degrees of freedom compared to spark plug. By varying the start and the duration of the diesel injection and by varying the diesel rail pressure one can influence not only the combustion phasing but also the pressure gradient, maximum pressure and the combustion duration in general.

Driving cycle results

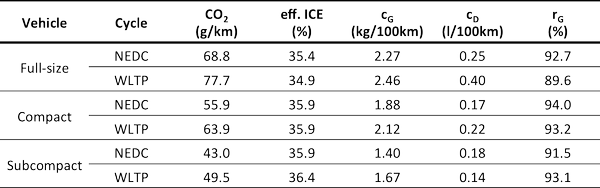

Table 1 shows the driving cycle results of proposed combustion concept used in a hybrid electric vehicle. The used cycles are the NEDC and the WLTP. The proposed engine concept runs on the test bench while the vehicle dynamics, the electric motor, the battery and transmission are emulated in software (hardware in the loop). Three different sizes of vehicles were emulated. The table shows the CO2 emissions, the mean efficiency of the internal combustion engine (ICE), the consumption of natural gas cG and the consumption of diesel cD. It also shows the energetic ration between natural gas and diesel rG.

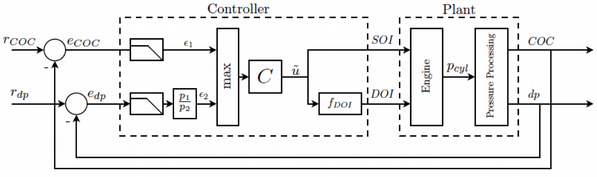

There are basically two reasons that make the control of the combustion system a challenging task compared to conventional spark ignition. Firstly, the additional degrees of freedom in a duel-fuel combustion system makes. Secondly, the duel fuel combustion control is prone to disturbances. There are fast disturbances like the operating point, the air/fuel ratio, the mass fraction of burnt gas, temperature and pressure at the beginning of the combustion, cycle-to-cycle variations the varying fuel quality of natural gas and diesel. There are also relatively slow disturbances as the engine temperature, ambient air conditions and the aging of the components.

Figure 4 gives an overview of the combustion control concept that allows for the control of the center of combustion COC and the maximum pressure gradient.

Ott T., Onder C., Guzzella L. Hybrid-Electric Vehicle with Natural Gas-Diesel Engine. Energies; 2013; 6: 3571-3592.

Ott T., Zurbriggen F., Onder C., Guzzella L. Cylinder Individual Feedback Control of Combustion in a Dual Fuel Engine. IFAC Advances in Automotive Control, Tokyo, Japan. 4 - 7, September, 2013.

Ott T., Zurbriggen F., Onder C., Guzzella L. Cycle Averaged Efficiency of Hybrid Electric Vehicles. IMechE Part D: Journal of Automobile Engineering; 2013; 227:78-86.

Nüesch T., Ott T., Ebbesen S., Guzzella L. Cost and fuel-optimal selection of HEV topologies using particle swarm optimization and dynamic programming. American Control Conference, Montreal, Canada. 27-29, June, 2012.

Ott T., Onder C., Guzzella L. How Much Fuel Can a Hybrid Electric Vehicle Save? International Advanced Mobility Forum (IAMF), Geneva, Switzerland. 8 - 9 March, 2011.

09.01.2014

external page 10 vor 10

12.09.2013

external page Interview with Tobias Ott

09.01.14 external page Tages Anzeiger

09.01.14 ETH Life

23.10.13 external page Automobilrevue

12.09.13 ETH Life

28.08.13 external page MIT Technology Review