Adaptive Model Predictive Control for Heat Pump Heating Systems

This page contains an archived project. It is no longer updated.

The heat pump heating systems in single family houses typically are controlled with a relay-type controller for the return flow temperature. This type of controller permits sufficient comfort for the residents, but generally it is unable to take into account the dependence of the heat pump's efficiency on the outdoor air temperature. Therefore the heat pump consumes more electrical energy and thus keeps the heating costs higher than necessary.

The main goal of this research project is to determine the required heating energy with regard to the thermal behavior of the building, the weather forecast, the power costs (high and low tariff), and the power cut-off times imposed by electric power providers. In addition, since a heat pump can only be switched on or off, the required heating energy has to be quantified. This is achieved by means of pulse-width modulation with regard to the optimal performance of the heat pump.

The Model Predictive Control (MPC) design technique is chosen for the development of the complex controller required to take all those effects into account. As an added benefit, this control strategy also allows the warm-water supply to be controlled. Furthermore, we are developing in this project a self-adapting MPC controller. Its function is to automatically detect the thermal behavior of the house and its heating system by on-line parameter identification techniques in order to adjust the controller parameters according to preset demands.

A dynamic test bench for brine-to-water heat pumps has been developed which allows the emulation of the thermal behavior of a virtual house as well as that of a fictitious earth probe. Thus the various control strategies may be tested and compared prior to their implementation.

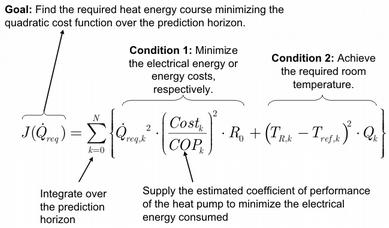

Instead of a steady-state heating characteristic curve, the model predictive control (MPC) method uses a mathematical model for the dynamic thermal behavior of the house and a predicted transient for the outdoor temperature in a control algorithm to optimize the duration of the heating energy portions as well as their distribution with regard to the power costs (high and low tariff), the power cut-off times, and the most energy-efficient operation of the heat pump. For the development of the control algorithm, the model predictive control approach using the LQ optimization is chosen (LQ: linear model for the system to be optimized, quadratic objective function for the optimization).

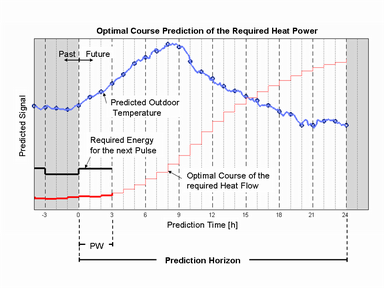

Using a linear dynamic second-order model of the house, the minimization problem can be solved analytically. By means of the predicted course of the outdoor temperature, the model predictive controller calculates the required heat energy over a prediction horizon of typically 24 h. Only the required energy for the next pulse is considered and at each timestep the MPC algorithm is recalculated.

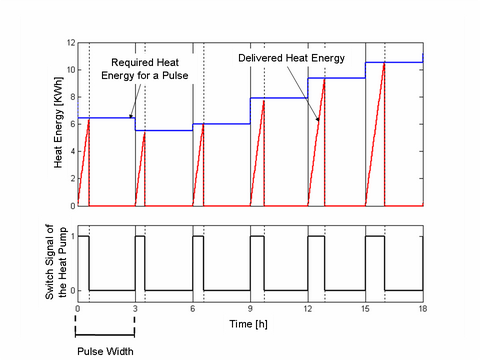

To transform the required heat energy into an on/off switch signal for the heat pump the pulse-width modulation (PWM) technique is used. The pulse width is kept constant (typically 3h). For each pulse the heat pump remains switched on until the required amount of energy has been delivered.

The results of the emulation with the new control algorithm have shown that the heat energy can be placed in a desired time interval more easily than with conventional controllers. The optimization algorithm ensures the minimization of the costs and electrical energy.