Energy Management of Hybrid Electric Vehicles

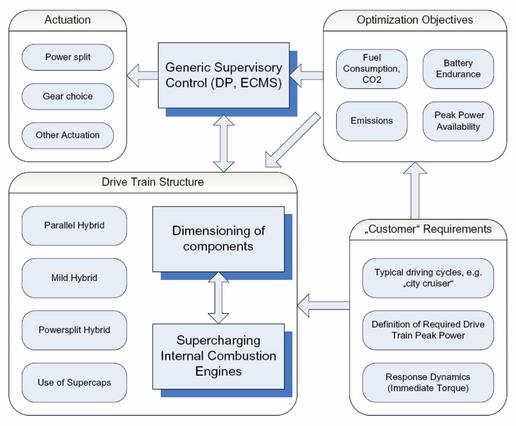

A large part of the worldwide CO2 emissions stems from the transportation sector which is dominated by conventionally driven vehicles. Conventionally driven vehicles, i.e. vehicles with only an internal combustion engine as the main power source, suffer from low efficiencies at part-load operation. Moreover, kinetic and potential energy cannot be recuperated since only friction brakes can be engaged during braking. To overcome these drawbacks, the vehicle can be equipped with at least one electric motor and a battery to build a hybrid electric vehicle. Such a configuration potentially allows for a considerable reduction of fuel consumption and hence CO2 emissions. However, the ultimate performance depends on the choice of the vehicle architecture, the component sizes and the coordination of these components (better known as supervisory control or energy management). In this project, all three aspects are considered. However, the focus lies on the development of energy management strategies since these strategies are the basis for the optimization of entire vehicle concepts.

Energy Management Strategies

The goal of an energy management strategy is to

- minimize fuel consumption (or equivalently CO2 emissions)

while satisfying constraints such as

- ensuring battery charge sustenance,

- meeting the emission standards,

- providing acceptable driveability, and

- enabling long component life times.

The most important degree of freedom to achieve this goal represents the power split actuator. The power split defines the distribution of the power that is delivered by the engine and the motor. Depending on the powertrain architecture, there are additional degrees of freedom such as the gear choice, clutch positions and the operating points of additional power sources.

Overview

We strive to develop systematic methods for the synthesis of energy management strategies of hybrid electric vehicles. These methods need to fulfill industrial requirements while being backed by profound theoretical fundamentals. Examples of industrial requirements include

- the simplicity of the methods to understand them,

- simplicity of the parameter tuning process,

- modularity to allow for adaptive as well as for predictive algorithms, and

- adaptability to arbitrary powertrain architectures.

The basis of all approaches is the analysis of an appropriately formulated optimal control problem. Then, reformulations of the objectives and constraints are investigated to achieve a problem structure allowing for the application of dedicated solution procedures. Depending on the intended use of the strategies (i.e. for component sizing, benchmarking or online control), different numerical optimization methods are employed:

- Sizing: convex optimization

- Benchmarking for online strategies: dynamic programming, Pontryagin's minimum principle

- Online strategies: equivalent consumption minimization strategy (ECMS), stochastic dynamic programming (SDP)